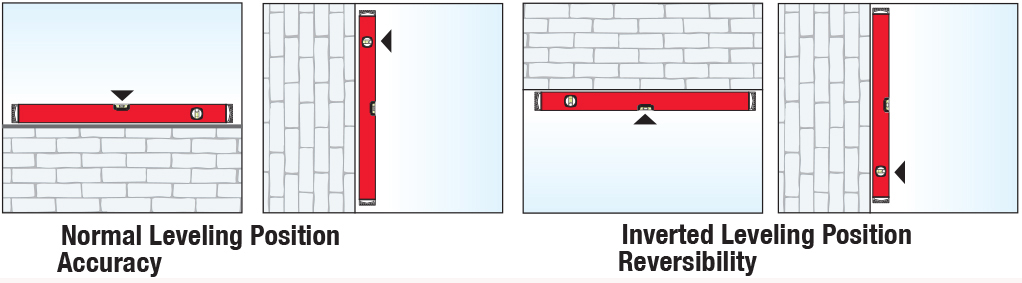

Reversibility refers to the accuracy of the level when used for inverted measuring. Normal position: the way the vial is normally calibrated – the vial is on the top side. Reversed position: the vial of the spirit level is reversed 180˚ from the normal position.

Not all levels are accurate in the reversed position. Ensuring reversibility requires special care starting from the vial production and through both assembly and calibration. Generally, the accuracy of spirit levels with reversibility -in the reversed position- tend to diverge between from the stated accuracy in normal leveling position.

Kapro’s contractors levels 905, 990, 995 and 985XL all offer full reversibility accuracy of ±0.5mm/m in both normal and reverse leveling positions.

Vial Sensitivity

The sensitivity of a bubble is defined by its radius. With very high vial sensitivity, the level will be more precise; but the bubble will move quickly and will be difficult to stabilize. With low sensitivity, the bubble will move slowly, be easy to stabilize but the level will lose precision. Usually, the sensitivity in the market is of 10mm/m which means that if you raise one end of a 1-meter long level by 10mm, the bubble will move by 2mm if the radius of the vial is 200mm.

Epoxy Locking

The way a vial is mounted on the profile has a direct effect on the durability of the spirit level. Epoxy locking of vial housings and vials guarantees that the level can better withstand the rough workplace environment and retain their factory-calibrated accuracy for the life of the level.

Most Kapro Spirit levels are epoxy locked.